CAREL@Host

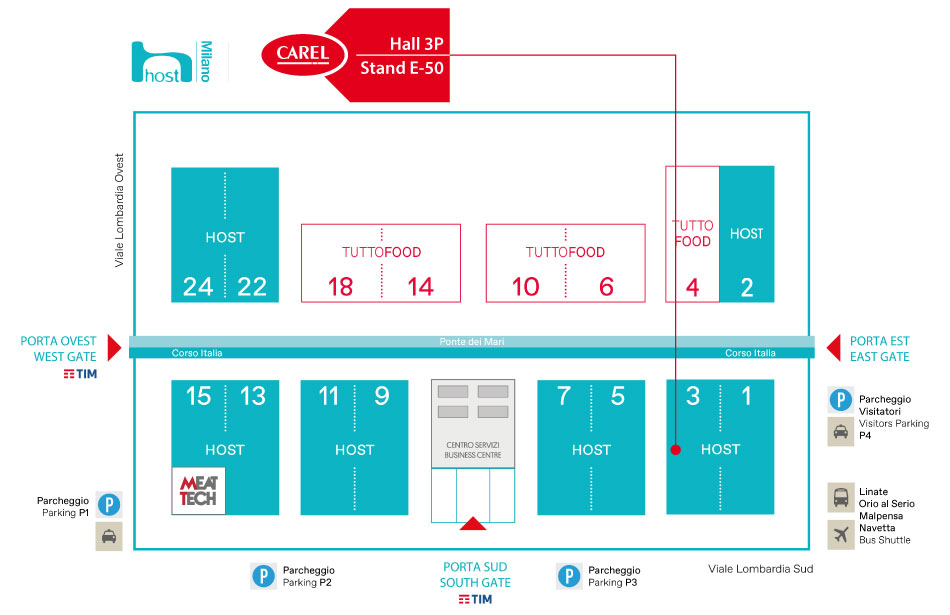

From 22 to 26 October 2021, CAREL participates at Host, the biennial catering and hospitality exhibition held in Milan. To celebrate this long-awaited international event, back in person, CAREL presents a new generation of control solutions for professional and commercial refrigeration, combined with an advanced range of connectivity services.

We are thrilled to be taking part in this event, Europe’s number one meeting for the food service market. The attentive and demanding visitors at Host make it the ideal stage for presenting our new solutions, the result of continuous investments to support our customers in facing the future challenges in this sector, such as sustainability, attention to design and a new user experience through the adoption of advanced IoT systems.

CAREL will be bringing its wealth of experience and innovation to this international hub, supporting all aspects of the food sector with solutions to meet the different needs of this market and the constantly evolving regulatory framework.

iJ, the new range of parametric controllers for commercial refrigeration featuring a customisable aesthetic design and innovative technical details, will be the star at the CAREL stand. Also highlighted will be Heosone, the solution for the control and management of plug-in refrigerated units that guarantees optimal energy efficiency through the use of DC inverter technology and natural refrigerants. The CAREL offering will be accompanied by multiple connectivity proposals based on IoT systems, developed to support every single product and application.

Know more: ij.carel.com

Host2021 - FAQ

Why are performance and reliability increasingly important in the professional refrigeration business?

-

ECODESIGN AND ENERGY LABELLING

Striving to improve unit performance is essential to be able to respond to the Ecodesign and energy labelling regulations in the professional refrigeration market (Ecodesign: (EU) 2015/1095, Energy Labelling: (EU) 2015/1094) and, from 1 March 2021, also commercial refrigeration (Ecodesign: (EU) 2019/2024, Energy Labelling: (EU) 2019/2018).

-

HIGH EFFICIENCY

The solutions that respond to the need for “energy efficiency” are based on the use of electronic controllers with smart management algorithms for refrigeration applications, extending to the adoption of plug&play solutions (serial cards and embedded AOs) for variable speed compressors (VCC); finally, there are fully integrated systems, such as Heosone, the complete solution for propane plug-in units that exploits all the advantages of DC rotary compressors and the excellent qualities of electronic valves.

-

RELIABILITY

To withstand the typically aggressive environments of professional kitchens, the controller needs to be particularly robust. This means electrical reliability, ensured by smart activation of loads and the ability to withstand unstable mains power supply conditions/mains voltage fluctuations, as well as mechanical reliability, guaranteed by IP65 protection and special protective resins on the electronic board.

How can design be used as a means of differentiation in the refrigeration business?

-

DESIGN

The design of refrigeration units is becoming more and more important, as it either enhances or tarnishes the appeal of the products on sale. Consequently, paying attention to the appearance of the controller fitted on these units means improving visual impact, without of course neglecting the features. Shapes, colours and materials together create the look of the unit, and combined with usability, practicality and durability maximise the value of the overall solution.

-

CUSTOM ELEMENTS

There is a growing need to characterise different applications through specific aesthetics and extend the family feeling across the entire product range, with the company’s own logo. The configuration flexibility and ease of customisation of the IJ platform make it possible for companies to define their own distinctive character and stand out clearly on the market.

What characteristics of refrigeration units need to be verified to best preserve meats, cheeses and sausages?

-

STABLE PRESERVATION

Keeping temperature and humidity in the right range protects the produce against any physical-chemical and biological alterations that could cause it to deteriorate. Furthermore, the humidity also needs to be kept at the right value to obtain the highest weight of the produce for sale, while guaranteeing minimum bacterial growth.

-

FOOD SAFETY

To ensure maximum food safety, the conditions of the unit need to be carefully monitored throughout the preservation process; compliance with the HACCP protocol is therefore essential in order to maintain the highest food quality. The capacity of the controller to log temperature and humidity values, as well as any alarms, and then easily export the logs, allows automated management of HACCP reports, thus reducing the risk of unwanted spoiling.

-

FLEXIBLE OPERATION / OPERATING MODE SELECTION

The storage of meats, cheeses and sausages often requires several stages: seasoning, maturation and preservation. Having just one cabinet for all of the different stages of the production process is a major advantage in terms of operating flexibility. The operating mode and corresponding settings can be quickly changed, so as to transform the cabinet based on the produce being seasoned, using the dedicated interfaces: from the touch panel to the “7 segment” display with icons.

What are the advantages of a connected cooler?

-

EASY INTERACTION VIA SMARTPHONE

The introduction of new wireless technologies such as NFC and Bluetooth has made it possible to shift the more complex operations to smartphones, using dedicated apps. Product temperature compliance control (HACCP), alarm notifications, parameter settings and dashboards with graphs of unit operation are some of the features available in the apps that improve the user experience, while the different user profiles provide secure access to the various programming areas.

-

MAXIMUM CONTROL WITH CLOUD SERVICES

The drive to increase connectivity also extends to remote interaction, with cloud services for the acquisition and analysis of IoT data, both specific to each individual asset, and aggregated, allowing constantly monitoring of asset performance. The information in the cloud can also be used for targeted maintenance, through initial diagnostics for planning more effective service and developing new business models.