Invisible but vital: relative humidity in the printing industry

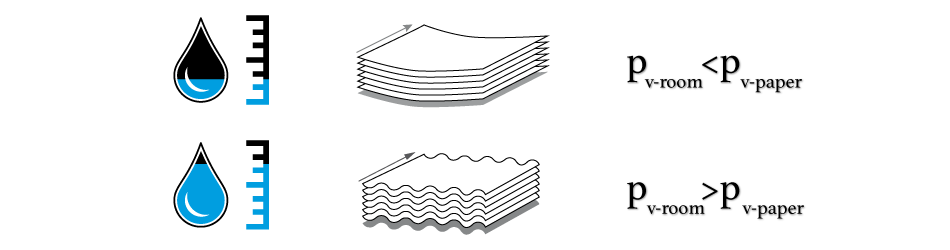

Paper is mainly composed of cellulose, meaning it is an intrinsically hygroscopic material and consequently maintaining a suitable moisture content (5-8%) is fundamental for preserving the desired workability and quality. If the relative humidity of the air is not properly controlled, direct and extended contact of paper with the air will negatively affect its characteristics. The difference in partial pressures between the moisture content of the paper and the humidity of the air tends to balance naturally, in accordance with the principles of physics. As a result, paper either absorbs from or gives off moisture to the surrounding air, causing a decline in its characteristics.

A 10% change in relative humidity changes the dimensions of the paper by around 0.1-0.2%, sufficient to affect processing speed and jam the printing machinery, causing economic damage. In the absence of relative humidity control, quality defects can easily occur due to improper adhesion of ink on the surface, producing considerable waste.

Relative humidity control is thus fundamental in ensuring continuity of operations and ensuring final product quality.

Download the "Air humidity in the printing industry" white paper

Electrostatic charges

Electrostatic charges

Controlling humidity limits electrostatic discharges that may damage electronic components.

Print quality

Print quality

Controlling humidity in printing processes avoids breakages, misalignments due to changes in dimensions and optimises ink absorption.

Worker health

Worker health

Maintaining the correct humidity level in the workplace increases operator comfort and reduces the spread of viruses and bacteria.

CAREL offers a wide variety of solutions for the management of humidity in the production environment, with adiabatic humidification being the best choice for these applications, due its dual advantage of both humidifying and partially counterbalancing the indoor thermal loads thanks to evaporative cooling.

Ducted humidification

humiFog Multizone is CAREL’s solution for duct installation, where a centralised air-conditioning system is already installed.

- High efficiency, thanks to low energy consumption (4 W per l/h) compared to isothermal solutions (750 W per l/h);

- Centralised humidification of the entire production plant;

- Rapid start-up and precise control.

In-room humidification

humiFog Direct and humiSonic direct are CAREL’s proposals for in-room humidification in the printing industry.

humiFog Direct and humiSonic direct are CAREL’s proposals for in-room humidification in the printing industry.

- Easy installation;

- Humidification concentrated in the most critical points of the production process;

- Absorption of the water droplets in small spaces.

Local supervision

Solutions for continuous monitoring of the humidified space and local control of the humidifiers.

Who Chose Us - Printing

Reset