Compressed air water atomisers

General characteristics

This product is available in CAREL CPQ, the sizing and selection tool that lets you independently find the right CAREL solutions for you, download the related documentation, receive support, and generate quotes and orders.

Compressed air humidifiers are the ideal humidification solution whenever a compressed air supply is available, as is the case in many industrial applications, even if humidification systems are often fitted with a dedicated air compressor. The humidifier essentially consists of a cabinet fitted with electronic controller that, using two independent connection pipe networks, supplies the spray nozzles with compressed air and water at the ideal pressure for instant operating conditions.

The units can be installed inside an AHU or directly in the room where humidity needs to be controlled. The greatest advantage of these atomisers is the minute dimensions of the droplets produced and their thorough mixing in the compressed air that, due to its speed, distributes the aerosol in the room and consequently allows quick absorption. These units can therefore be readily used for direct cooling in rooms, and are ideal for the textile industry, wood and paper processing, and storerooms, where there is almost always a supply of compressed air.

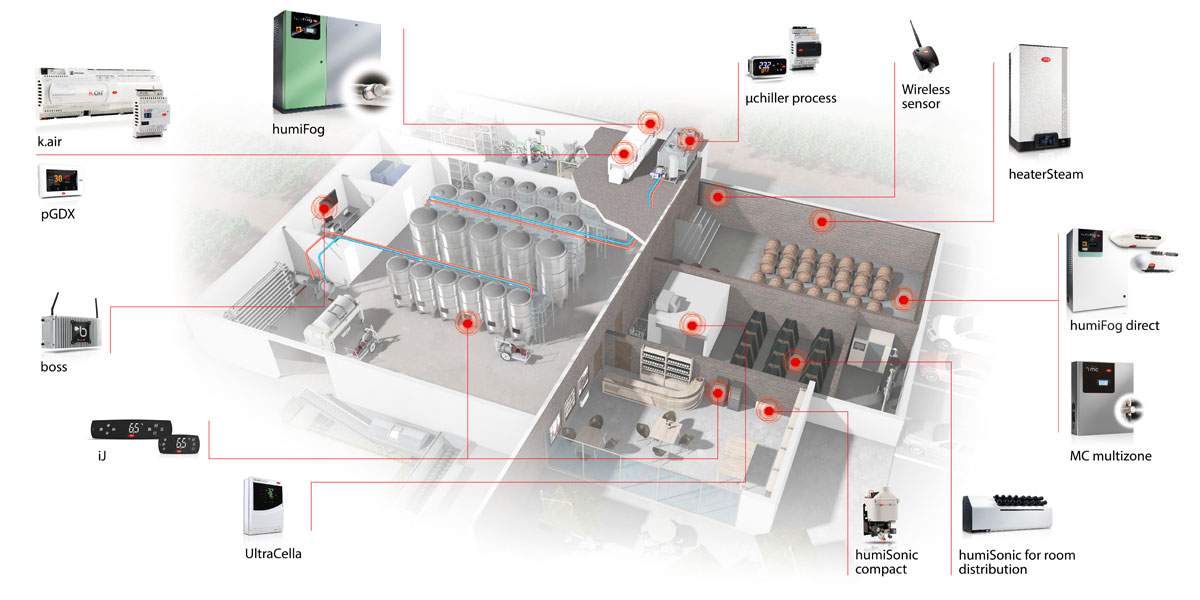

mc multizone features an electronic controller that manages the supply of water and compressed air to the nozzles.

Water atomisation is managed by an external control signal or, in the case of stand-alone control, so as to maintain the humidity/temperature set point. The unit also manages a series of automatic cycles, such as nozzle cleaning and washing.

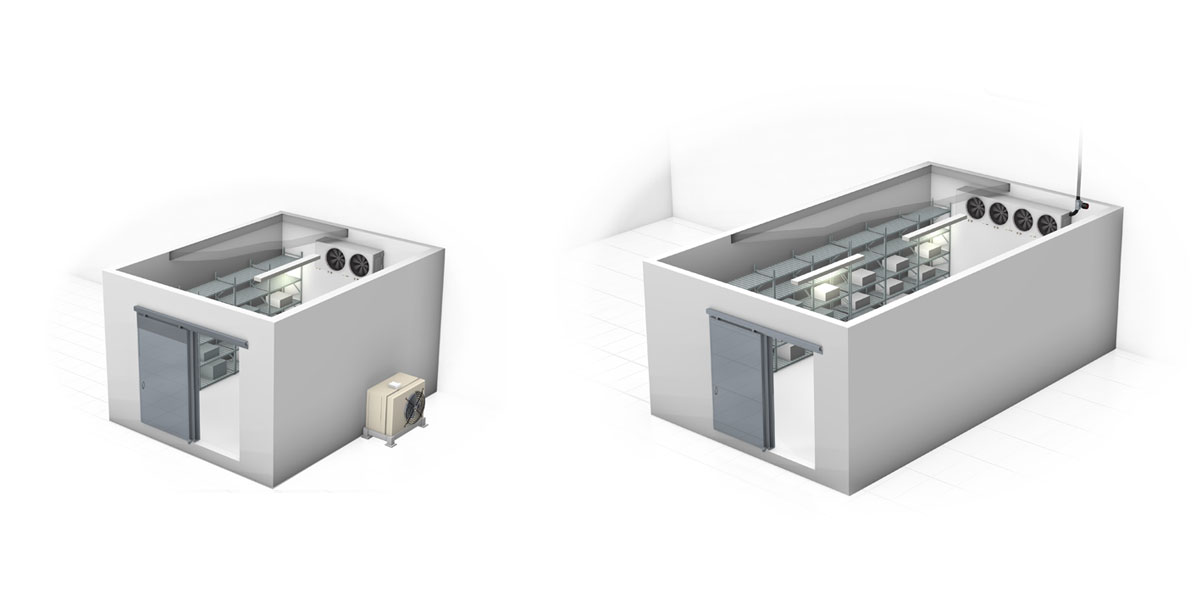

The system has the ability to control humidity independently in multiple zones (rooms, AHUs, cold rooms) using a main/secondary layout. The layout has one master and multiple clients (up to 5) connected in a pLAN. The master is fitted with a display for accessing the readings, viewing the status and messages on the master and clients. The clients have their own internal controller and can be set to continue operating even if connection to the master is interrupted.

Create a free account and access CAREL CPQ now.

-

Plus

The main/secondary configuration can be used for:

- high capacity: applications in rooms or ducts where more than 230 kg/h of humidification is required, and thus more than one mc cabinet. The control signals (probes, external signals, limit probe) are connected to the master only. The master and the clients generate a humidification/cooling capacity that is proportional to demand and their capacity. This allows systems to be developed with a capacity up to 1380 kg/h;

- multizone applications: applications in multiple zones, rooms or ducts, each with its own humidity/temperature set point. All the parameters, status information and messages for all the cabinets can be viewed and edited from the user interface on the master. Installations in large spaces can be divided into zones, each with their own humidity/temperature probe, using the multizone main/secondary system.

- Automatic nozzle self-cleaning system: each cabinet, master and client, periodically activates a cycle for drying and cleaning the atomising nozzles. A special cleaning piston inside the nozzle is periodically pressed, by a spring, into the opening of the nozzle, removing any mineral salts and considerably reducing the need for cleaning.