Atomisers- evaporative cooling

General characteristics

This product is available in CAREL CPQ, the sizing and selection tool that lets you independently find the right CAREL solutions for you, download the related documentation, receive support, and generate quotes and orders.

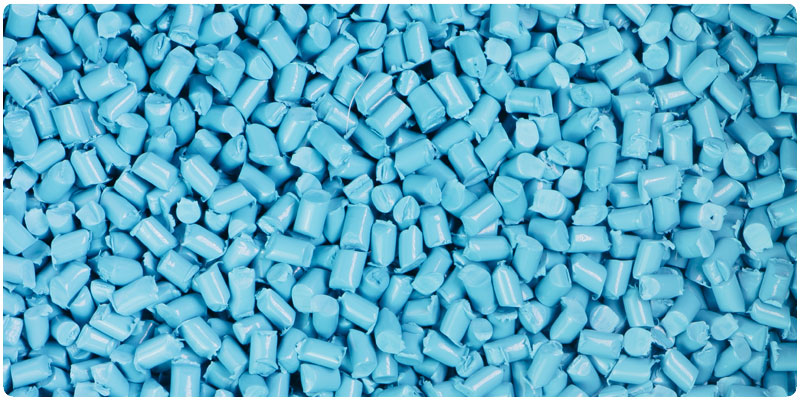

"Evaporative Cooling" is the process in which water cools the air through evaporation. For this to happen spontaneously, without the contribution of external energy, the water must be atomised in the air as very fine water droplets which, having a lower surface tension than the surrounding air, evaporate into the air.

Why does the air cool down?No contribution of external energy is necessary, however, owing to its nature, the water evaporation process requires a certain amount of energy. This energy is removed from the air itself which, in order to absorb the water must release sensible heat, thus lowering its own temperature.Every kilogram of water that evaporates absorbs 0.69 kW of heat from the air. This is how the dual humidification and cooling effect of the air is obtained through the Evaporative Cooling process, which in many air handling applications represent two desired effects.Energy SavingThe rapid development of evaporative cooling in HVAC applications is surely due to its very low energy impact. If we compare the cost for energy regarding Evaporative Cooling with that of other types of air transformations (e.g. humidification with steam emission or air cooling via chiller), it can be seen that the energy saving is considerable. The only energy required is for water pressurisation, which is sent to the atomiser nozzles by a pump. Consumption is about 4 to 8 W for every l/h of atomised water. Optimist atomisers CAREL supplies a complete range of products that make use of the principles of evaporative cooling and all its advantages. The standard composition of these products is:- cabinet, containing the pump for pressurising the water, an inverter and an electronic controller for modulating the production of atomised water instant by instant;

- atomiser nozzles, able to atomise the water into very fine water droplets (in the order of a few hundredths of a millimetre), extending the heat exchange surfaces.

- distribution system, composed of stainless steel manifolds, atomiser nozzles and drain valves, in order to guarantee emptying.

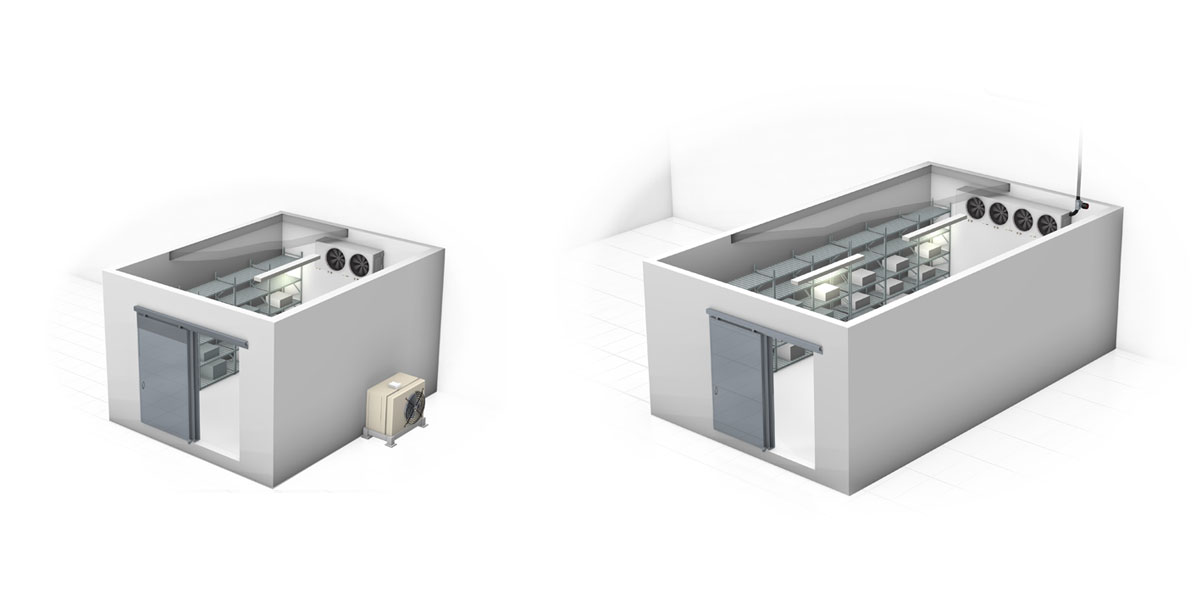

Optimist atomisers CAREL supplies a complete range of products that make use of the principles of evaporative cooling and all its advantages. The standard composition of these products is:- cabinet, containing the pump for pressurising the water, an inverter and an electronic controller for modulating the production of atomised water instant by instant;

- atomiser nozzles, able to atomise the water into very fine water droplets (in the order of a few hundredths of a millimetre), extending the heat exchange surfaces.

- distribution system, composed of stainless steel manifolds, atomiser nozzles and drain valves, in order to guarantee emptying.

Create a free account and access CAREL CPQ now.

-

Plus

- energy saving: combines adiabatic humidification and evaporative cooling in a single global solution for energy saving within the AHU.

- pressure loss management: optiMist guarantees real energy savings, assuring a very low pressure drop at the fans (30 Pa);

- controlled atomisation: in order to completely exploit the potential of evaporative cooling and without waste, it is necessary to have very accurate control of the amount of water atomised, instant by instant. By combining the action of the inverter and the modulation circuits, Optimist can precisely follow temperature and humidity demand;

- hygiene: thanks to the materials used, the design of the distribution systems without stagnation points and the automatic washing systems managed by the electronic controller, Optimist is a hygienically safe solution for adiabatic humidification and evaporative cooling within the AHU